釀酒工業用製程線上二氧化碳, 溶氧自動分析儀器及採樣系統

Dr. Thiedig – your partner for sampling systems and analysis technique

製程線上微量溶氧分析儀 – DIGOX 5 Oxi – On-line-Analyzer

The Stationary DIGOX 5 – Oxi

The monitoring of oxygen is one of the most important aspects of quality control in the brewing process. Excessive oxygen levels affect the quality and shelf life of beer.

A fast and reliable method of oxygen measurement is essential to be able to react immediately and correctly whenever oxygen is registered. Digox 5 is our solution.

Ease of operation for process reliability – The new DIGOX 5

The all-new electronics ensure continuous online quality control for your production.

Data interfaces, analog outputs, alarm and limit value relays provide almost unlimited possibilities for data management and process control.

With its automatic calibration, the robust Thiedig sensor is designed for virtually maintenance free, continuous operation. Automatic re-calibration can be activated at any time during measurement operation or at freely programmable intervals – thus allowing accurate and reliable measurements at any time.

The Thiedig sensor – An intelligent measuring system

The Thiedig sensor works on the basis of the cathodic reduction of oxygen at a polarised electrode.

The Thiedig sensor makes use of this electrochemical principle by means of the potentiostatic arrangement of three electrodes. Unlike with other measuring methods the sample liquid (beer or other beverage) is itself used as an electrolyte, and the measurement is performed directly without the need for a membrane.

Direct contact means very fast response times. If oxygen penetration occurs, then the measuring cell is automatically rinsed free, and the oxygen level does not need to be reduced in the cell.

DIGOX 5S 線上啤酒溶氧分析儀目錄下載 (![]() PDF 491 KB)

PDF 491 KB)

The advantages :

– The sensor works drift-free and reliably

– Extremely short response times due to direct contact with the sample

– Unlike membrane sensors the system allows exact temperature compensation over a wide range

– The nature of the system means that there in no zero-point drift

– The sensitivity of the sensor can be checked at any time without interrupting measurement

The stationary DIGOX 5 –

The ideal system for process measurement

The Digox 5 is a continuous analyser for oxygen measurement in drinks production.

The fixed version is designed for the harsh conditions to be found in beverage production.

The measuring system is robust and dependable, even where there are strong fluctuations in pressure and the environment is damp. The measuring system can be sterilized to a temperature of 120°C. and is therefore fully suitable for CIP.

Applications

– Monitoring oxygen content during wort aeration

– Monitoring oxygen content in unfiltered beer prior to filtration

– Monitoring oxygen content after filtration

– Monitoring oxygen content after carbonization

– Monitoring oxygen content before bottling

– Monitoring oxygen content in the degasified water.

The stationary DIGOX 5 –

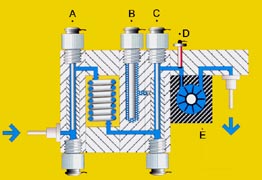

Process measurement in a bypass

The fully sterilisable Thiedig sensor is operated in a bypass. A pressure gradient of about 0.3 bar is required for this purpose. This pressure gradient is normally achieved by means of a Venturi tube mounted in the main pipe. The Venturi tube is a hydrodynamically shaped pipe narrowing, which creates a pressure difference at that point without noticeable loss of pressure

in the main system.

This pressure difference is used for a secondary flow of approx. 10 litres per hour through the Thiedig sensor. It is also possible to use a plant’s existing pressure gradients, for example, at a pump or pressure reduction valve.

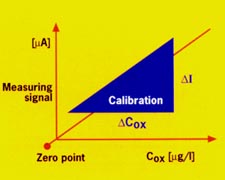

Accuracy at all times – Thiedig active calibration

The Thiedig sensor is the only sensor that can be calibrated without interrupting measurements.

The calibration takes place in the measuring sample, and the calibration point is within the measuring range. The active calibration is based on Faraday’s law and a volume measurement.

It is therefore based on measurement variables independent of the system. Using electrolysis, an exact concentration of oxygen is created in a flow cell by means of a set current and a known flow rate. This calibration concentration establishes the measuring sensitivity of the sensor.

The method makes it possible to determine the correlation between oxygen content and measuring current.

The microprocessor extrapolates these exactly through the zero point, which, in the case of the Thiedig sensor, is fixed by the nature of the system.

Advantages

– Calibration is fast and automatic

– If doubts arise, measurement values can be double-checked by immediate re-calibration without any interruption to measurement

– Since calibration takes plate in the measurement sample, there are no external effects from any other substances

– The data are stored automatically and can be recalled and recorded

and easy to maintain

simple and exact

The stationary DIGOX 5 –

The specialist for particular tasks

Oxygen monitoring for wort aeration in beer production

The aeration of beer wort before fermentation is of decisive importance for the exploitation of the fermentation process. Too little aeration of the wort results in premature death of the yeast cells and thus incomplete fermentation.

The conditions linked to wort ventilation, such as the suspended matter content and the need for frequent cleaning, make reliable measurement particularly difficult at such a location.

The special design of the Digox 5 for wort measurement provides a reliable solution for this particular task.

A special measuring electrode supplies dependable measurements from the beer wort.

A fully sterilisable micropump prevents flow rate fluctuations through the measuring system.

DIGOX 5 – process measurement after water degasification

Degasified water is playing an ever increasing role in beverage production. Oxygen-free water is also contributing to achieving low levels of oxygen pollution in production.

Because of its low oxygen values water degasification makes high demands on a measuring system.

The Digox 5 is also the appropriate measuring system at this critical point in the production process. Oxygen values are measured with a resolution of 1 µg/l. exactly and with replicability, even in the range below 20 mg/l.

Technical data

| Analyzer | DIGOX 5 type EC stationary |

| Internal measuring ranges | measuring ranges : 0.001 – 20.00mg/l |

| Display | 0.001 – 20.000 mg/l, digital in mg/l O2 |

| Accuracy | ▽1% based on the measuring range final value |

| Recorder measuring ranges | 2 measuring ranges between 0.2 mg/1 and 20 mg/l |

| Measuring range I 0.200 – 2.000 mg/l programmable in 0.2 mg/l steps | |

| Measuring range II 2.000 – 20.000 mg/l programmable in 2 mg/l steps | |

| Data interfaces | RS 232, Option ; RS 485 |

| Limit values | 4 freely programmable limit values 1 load relay |

| Signal outputs | 3 outputs for measuring ranges, temperature, flow rate |

| – galvanically separated, | |

| – adjustable for 0 … 20 mA or 4 … 20 mA | |

| Response time (t=90%) | < 10 s |

| Permissible ambient temps. | -5 … +40°C. |

| Sample temperature | 0 … 60°C. (compensated up to 50°C.) up to 120°C. during system cleaning |

| Sample pressure | max. 10 bar |

| Sample flow rate | 3 – 18 l/h |

| Calibration | fully automatic Thiedig active calibration with auto-check, error message and report |

| Power supply | 90 … 240 VAC power adapter plug |

| Connected load | 10 VA |

| Protective system | IP 65 |

| Weight | approx 6.5 kg |

| Dimensions | 58x 33 x 13 cm |