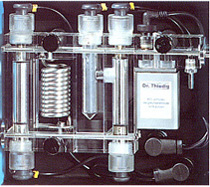

釀酒工業用製程線上二氧化碳, 溶氧自動分析儀器及採樣系統

Dr. Thiedig – your partner for sampling systems and analysis technique

可攜帶微量溶氧分析儀 – DIGOX 6 Oxi – Portable

DIGOX 6 – A new dimension in trace oxygen measurement

Digox 6 is a new concept in oxygen measurement in beverage production.

Its all-new electronics open up numerous possibilities for oxygen

measurement and data processing in the laboratory and in production. The tried and tested measuring method employing an open electrode is reliable, exact and maintenance-free.

The automatic calibration system, which, in just a few seconds, can check and correct the measuring sensitivity of the sensor, provides the user with absolute dependability for the accuracy of measurement values at any time.

The Digox 6 makes possible both individual or test measurements and continuous monitoring of your plant.

The Thiedig sensor – The intelligent measuring system

– The Thieidg sensor works on the basis of the cathodic reduction of oxygen

at a polarised electrode.

– The Thiedig sensor makes use of this principle by means of the

potentiostatic arrangement of three electrodes.

– Unlike in other measuring methods the sample liquid (beer or other

beverage) is itself used as an electrolyte, and the measurement is

performed directly without the need for a membrane.

– This results in very fast response times. If oxygen penetration occurs,

then the measuring cell is automatically rinsed free. The oxygen level

does not need to be reduced in the cell.

Accuracy at all times

The advantages of Thiedig active calibration

– The automatic calibration provides you with complete dependability in the

shortest possible time

– The measurement values can be double-checked by re-calibrating at any

time without interruption to measurements

– Since calibration takes place in the measurement sample, there are no

external effects from any other substance

– The data are stored automatically and can be recalled and recorded

DIGOX 6 – The ideal instrument for process control

The Digox 6 is the ideal instrument for trace oxygen monitoring as part of overall process control. It is ready at all times without long preparation or run-in times.

The integrated automatic calibration allows the checking of the measuring sensitivity during the first measurement and so ensures the total dependability of the measurement data.

The addition of the touch memory system and the new data logger enables clear, unmistakable allocation of the oxygen values and the accompanying measurement conditions to the respective measuring point,date, time and process controller. The Digox 6 can be deployed at any point of the production process.

Measurements in degasified water are possible as measurements in beer wort or unfiltered liquid.

A high-power, nickel-metal hybrid accumulator battery allows for more than 8 hours of independent operation.

Information required about each measurement process is provided via the unit’s clearly laid out display. straightforward messages provide information about the operating state or problems, so that exact measurements are guaranteed at any time. As an all-round, portable instrument the Digox 6 is the ideal control instrument for checking permanently installed equipment, or as a variably employed solution for small plants, or else as a substitute for malfunctioning permanent oxygen detectors.

In this application, the power supply comes via the mains power adapter, without affecting the capacity of the accumulator.

DIGOX 6 – Measuring instrument plus intelligent software

The Digox 6 features a high-powered electronic control unit. The self explanatory menu operation and straightforward graphic display make it simple and convenient to work with the new instrument.

All parameters relevant for the measuring, as well as the date and time, are displayed simultaneously.

Together with our new Digox WIN software and touch memory system, the new electronic unit provides a variety of new applications.

All these features mean that the Digox5 is able to measure, record and sort data.

The touch memory system

“Touch-memories” are small data stores that can be programmed individually.

Made of stainless steel, they are no larger than a small coin. They can be attached anywhere and require no maintenance.

Touch-memories enable the individual identification of each measuring point.

Digox 6 can store each identification code in its data logger, and thus be able to assign each measurement to a particular measuring point. Mix-ups are therefore impossible.

The time and date, as well as the time of previous measurements can be checked

DIGOX WIN

Digox WIN is the PC user software for analysing the measurements and for diagnosis of the measuring instrument.

Digox WIN runs under WindowsTM and meets all the requirements of modern

data processing in the laboratory :

– Read-outs from the data logger

– Conversion to ExcelTM

– Presentation of the data as tables or graphs

– Simultaneous online presentation and logging of measurements

Digox WIN has the ability to communicate.

You can set up direct contact with our service hotline via a telephone modem for the following :

– upgrading features for special applications

– receiving remote diagnosis and service, and so cutting out

unnecessary shipment delays

– subsquent activation of new options

DIGOX 6 手提式啤酒溶氧分析儀目錄下載 (![]() PDF 491 KB)

PDF 491 KB)

DIGOX 6 in the lab – Oxygen measuement in bottles and cans

Oxygen measurement in bottles and cans is one of the most important measurements for quality assurance in drinks plants.

The measurement also provides information about how well the bottling plant is functioning.

The Digox 6 provides a system for total oxygen determination in filled bottles and cans which allows the calculation of the total oxygen from just one measurement of the dissolved oxygen.

This procedure is based on the method described by K. Uhlig*. Phase parity is established in the sample between head-space and fluid phase with the Thiedig bottle turning device. Once the head space volume has been determined, the dissolved oxygen content is measured with the help of the Thiedig sampling device and the Digox 6.

Total oxygen determination with the Digox 6 system

Technical data

| Analyzer | DIGOX 6 type EC portable |

| Internal measuring ranges | measuring ranges : 0.001 – 20.00 mg/l |

| Display | 0.001 – 20.000 mg/l, digital in mg/l O2 |

| Accuracy | ▽1% based on the measuring range final value |

| Recorder measuring ranges | 2 measuring ranges between 0.2 mg/1 and 20 mg/l |

| Measuring range I 0.200 – 2.000 mg/l programmable in 0.2 mg/l steps | |

| Measuring range II 2.000 – 20.000 mg/l programmable in 2 mg/l steps | |

| Data interfaces | RS 232, Option ; RS 485 |

| Data logger | for 200 individual measurement values and 1000 values as a series, |

| optional: 3000 measurement values as a series | |

| intervals for measurements in series are freely programmable | |

| Limit values | 4 freely programmable limit values 1 load relay |

| Signal outputs | can be set for 0…20 mA or 4…20 mA |

| Response time (t=90%) | < 10 s |

| Permissible ambient temps. | -5 … +40°C. |

| Permissible sample temps | 0 … 60°C. (compensated up to 50°C.) |

| Sample pressure | max. 8 bar |

| Sample flow rate | 3 – 18 l/h |

| Calibration | fully automatic Thiedig active calibration with auto-check, error message and report |

| Power supply | 90 … 240 VAC power adapter plug., 12V NiMH-accumulator for approx. 8 hours |

| Connected load | 13 VA |

| Protective system | IP 65 |

| Weight | approx3. 8 kg |

| Dimensions | 27 x 33 x 14 cm |